Cryogenic Insulation - InsulPOX®

InsulPOX®, an Insulating Polymer Concrete Overlay (IPC) for Cryogenic LNG Terminal Spills (Secondary Containment) and other cryogenic applications such as liquid oxygen and nitrogen.

Stemming from research conducted with Brookhaven National Laboratory, ChemCo Systems is proud to announce a large scale installation of CCS InsulPOX® at an LNG terminal facility in New York. InsulPOX insulation layers have also been installed in a newly constructed U.S. gulf coast LNG liquification and export terminal that recently began export operations. InsulPOX (in panel form) has also recently been specified at a U.S. Navy base for a new LNG terminal and power plant under construction at Guantanamo Bay.

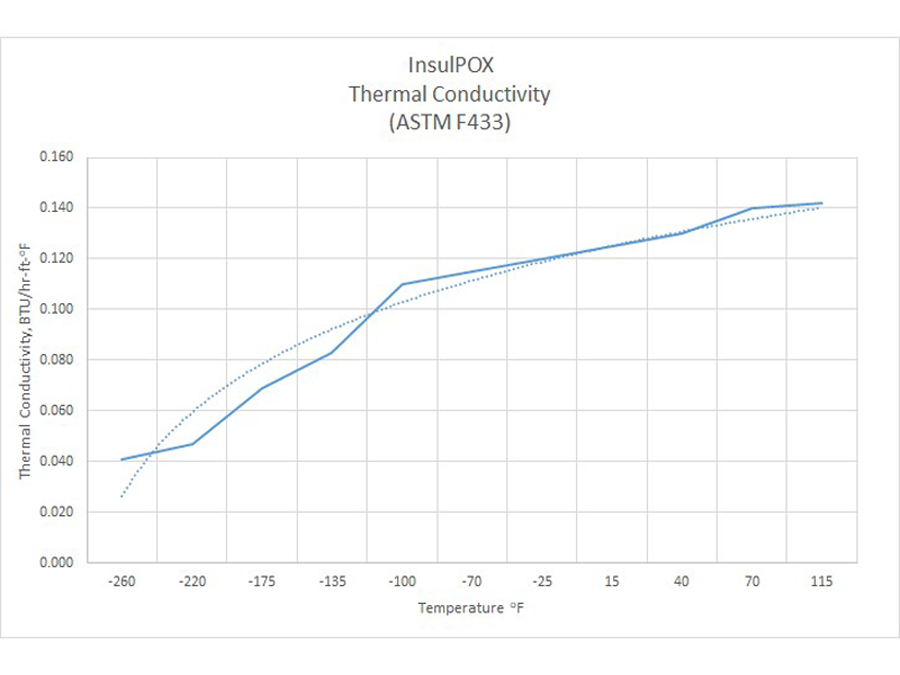

InsulPOX epoxy thermal insulating polymer concrete (IPC) is used on the surface of concrete floors and walls of secondary containment trenches and sumps at LNG terminals. InsulPOX is a three-component liquid that after mixing cures to form a low modulus, toughened polymer overlay formulated specifically for exterior applications where cryogenic thermal insulation is required. This lightweight ~3/4-1" (19-25 mm) thick overlay system reduces the evaporation rate of spilled LNG, thus reducing the vapor plume and lowering the concentration of LNG (methane gas) in the atmosphere below its flammable point. It also provides protection to the concrete and reinforcing steel from potential fracturing and embrittlement by insulating from the -262°F LNG boiling liquid should a spill occur. InsulPOX has been tested to -320°F which is the boiling point of liquid nitrogen.

InsulPOX's flexibility and toughness provide excellent mechanical and thermal shock resistance. Its long mixed work life and low exotherm make installation of the liquid pre-polymer mix hassle-free. InsulPOX can be installed seamlessly in-place on floors or cast in place on walls. Optionally, InsulPOX precast panels are also available in multiple sizes for quicker installation (including 4' x 8' panels), particularly in large area trenches or sumps. These panels can be easily handled by a 2 person crew.

InsulPOX can also be used to protect concrete and steel from cryogenic thermal shock and embrittlement resulting from liquid oxygen (O2) or liquid nitrogen (N2) spills. We are excited to contribute to the growth and safety of today's and future LNG terminals with this high performance and mechanically tough cryogenic insulation.

Why select InsulPOX?

- Slows Evaporation of Spilled LNG by Reducing the Heat Transfer of Underlying Concrete.

- Lowers the Airborne Concentration of Evaporated Vapors to Avert Explosive Levels.

- Protects Concrete from Cracking and Flexing Due to Exposure to -260°F (-160°C) LNG Liquid.

- Protects Reinforcing Steel from Cryogenic Embrittlement.

- Very Tough Polymer--Resistant to Mechanical and Thermal Shocks.

- Provides Seamless Installation.

- Field Repair Uses Non-Sag Version.

- High Compressive and Tensile Strengths Tolerates Foot* and Light Vehicle Traffic.

- Can be Installed in the form of Precast Sheets for Rapid Construction.

- Far Tougher and Easier Field Repair than Alternate Fragile Insulating Materials.

InsulPOX has been installed in a large west coast major league baseball stadium as a thin layer repair of spalled concrete in a a balcony flooring area and has performed well in a heavily foot trafficked area. Call us for pictures if interested 650-261-3790.

Link to InsulPOX product data sheet.

Below is a close-up of 3/4" precast sheets of InsulPOX overlaid on the faces of precast concrete trench sections for secondary containment of LNG piping trenches.

Tell us about your project

CALL 650-261-3790.